IMAGE GALLERY

Copyright 2023 Micro Tool Company

Micro Tool Company, Inc. 284 Brodhead Road Bethlehem, PA 18017 610.882.3740 fax 610.882.3776

MEET OUR STAFF

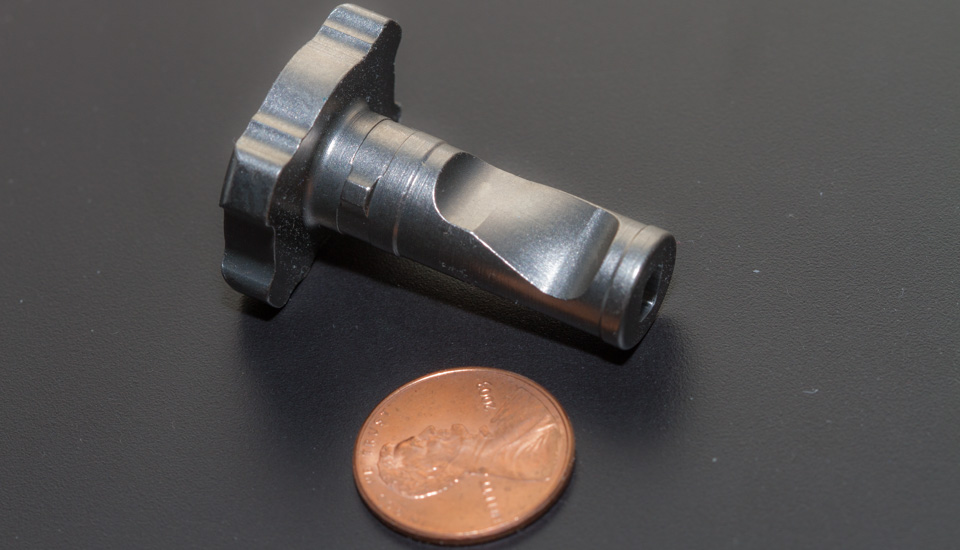

SEMI-AUTOMATIC SHOTGUN BOLT HEAD PRODUCED BY MICRO TOOL COMPANY

With over 50 years of experience, our extensive knowledge of modern CNC Swiss Machining and special processes gives us a competitive advantage. This project required us to precisely control the geometry and tolerance of this critical firearm component to allow for multiple post machining special processes which all affect the finished part size. These included austemper heat treating, shot-

Semi-Automatic Shotgun Bolt Head

Product Description |

Bolt Head for a Semi- |

Processes/Capabilities Applied |

CNC Swiss Turning, drilling, boring, milling, heat treating, shot peening, nickel/teflon coating |

|

Equipment Used to Manufacture Part |

32mm CNC Swiss- |

|

Part Dimensions |

1.070" OD x 1.410" long |

|

Tightest Tolerances |

+- |

|

Material Used |

AISI 4340 Alloy Steel |

|

Surface Finish Requirements |

32 micro inch RA |

|

Special Processes |

Austemper Heat Treat, Shot- |

|

Production Run Volume |

6000pcs |

|

Notes of Interest |

Demonstrated Process Capability of better than 1.33 Cpk |